Falling Lithium Prices Are Making Electric Cars More Affordable

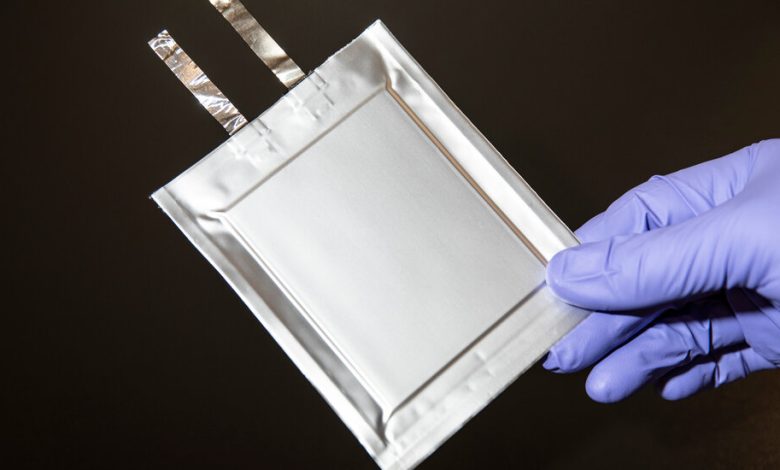

Lithium, the common ingredient in almost all electric-car batteries, has become so precious that it is often called white gold. But something surprising has happened recently: The metal’s price has fallen, helping to make electric vehicles more affordable.

Since January, the price of lithium has dropped by nearly 20 percent, according to Benchmark Minerals, even as sales of electric vehicles have soared. Cobalt, another important battery material, has fallen by more than half. Copper, essential to electric motors and batteries, has slipped by about 18 percent, even though U.S. mines and copper-rich countries like Peru are struggling to increase production.

The sharp moves have confounded many analysts who predicted that prices would stay high, or even climb higher, slowing the transition to cleaner forms of transportation, an essential component of efforts to limit climate change.

Instead, the drop in commodity prices has made it easier for carmakers to cut prices for electric vehicles. This month, Tesla lowered the prices of its two most expensive cars, the Model S sedan and Model X sport utility vehicle, by thousands of dollars.

That followed cuts in January by Tesla to its more affordable Model 3 and Model Y, and by Ford Motor to its Mustang Mach-E. The average price of an electric vehicle in the United States fell by $1,000 in February compared with January, according to Kelley Blue Book.

“For electric vehicles, the major roadblock is cost,” said Kang Sun, the chief executive of Amprius Technologies, a young battery maker that this month announced plans for a factory in Colorado. The falling price of lithium, he said, “is going to promote E.V. sales.”

Dr. Sun thinks prices could fall much further because demand for the metal has not risen as fast as some in the industry expected.

As with any commodity, there is a wide range of opinion on what has caused the recent drop in prices and on how much lithium will cost in the coming months and years.

Some analysts said the falling price of lithium was caused by short-term factors like slowing sales growth in Europe and China after subsidies for electric car purchases expired. But other industry experts said the drop suggested that new mines and processing plants were solving the lithium problem sooner than many analysts had thought was possible.

Even after falling so much, lithium prices remain so high that mining and processing the metal is an unusually profitable business. The metal, uniquely suited for batteries because of its ability to store energy, costs from about $5,000 to $8,000 per ton to produce. It sells for 10 times that amount, according to Mobility Impact Partners, a private equity firm based in New York that invests in the electric vehicle industry, among other areas.

Given those fat profit margins, investors and banks are eager to invest in, or lend to, mining and processing projects. The federal government is awarding grants worth tens of millions of dollars to lithium prospectors and processors.

“You can’t have profit margins that are 10 times what it costs to extract,” said Shweta Natarajan, a partner at Mobility Impact who has analyzed the lithium market. “You will see that come down.”

“Financing is very easy to come by,” Ms. Natarajan added. “There is no reason to think you wouldn’t have new projects opening up to meet any shortages.”

But others, including members of the Biden administration, are less confident. The supply of lithium has to increase by 42-fold by 2050 to support a transition to clean energy, said Jose W. Fernandez, the under secretary for economic growth, energy and the environment at the State Department.

“We have to find additional sources of supply because 42 times is a lot,” Mr. Fernandez said in an interview. “Right now, we don’t have enough.”

There is plenty of lithium in the world. But it was not considered very valuable until sales of electric vehicles began to take off in the last few years. As demand soared, the industry rushed to start new mines, and refineries increased their capacity to process the ore.

Lithium, the common ingredient in almost all electric-car batteries, has become so precious that it is often called white gold.Credit…Gabby Jones for The New York Times

“The mining is not what is driving the costs,” said Bold Baatar, the chief executive of the copper production unit at the mining giant Rio Tinto. “It’s the availability of processing facilities.”

Most lithium refineries are in China, and few managers and engineers outside that country know how to build processing plants. Beijing’s near-monopoly on an essential resource alarmed the Biden administration, which has allocated billions of dollars to encourage companies to develop lithium mines and refineries in the United States or in countries with which it shares close political and economic ties.

Supplies of lithium and other critical materials are a national security issue, Mr. Fernandez said. Last year, the administration established the Minerals Security Partnership, he said, a group that includes the European Union and 12 industrialized nations, including Australia, Japan and Britain, to locate mining opportunities and financing, and to promote recycling.

The Department of Energy is doling out $3 billion in grants to create a domestic battery supply chain. In addition, the Inflation Reduction Act, which Mr. Biden signed into law last year, provides tax credits for battery production.

American Battery Technology was awarded a grant by the Energy Department to help it build a lithium refinery and a battery-recycling facility in Nevada. The company is also developing a lithium mine in the state.

Ryan Melsert, the chief executive of American Battery Technology, attributed the recent decline in lithium prices to temporary factors like a seasonal slowdown in electric vehicle sales in China. “We expect to see very high prices for the foreseeable future,” Mr. Melsert said.

Vivek Chidambaram, the senior managing director for strategy at Accenture, the consulting firm, also expects the decline to be ephemeral. Lithium prices have fallen because sales of electric vehicles, while still brisk, are not growing as fast as automakers expected, he said. That has led suppliers to produce more than is needed.

“There was a time when people believed electric vehicles would grow very rapidly,” Mr. Chidambaram said. “Then the reality of how fast they were actually growing caught up.” He expects lithium prices to fluctuate for the next several years.

Automakers, fearful of lithium shortages and rising prices, have taken steps to ensure a steady supply. They have signed contracts with lithium suppliers that require them to buy certain quantities of the metal. In some cases, carmakers are getting into the lithium business more directly. Tesla said this month that it would build a lithium processing plant near Corpus Christi, Texas.

General Motors said in January that it would invest $650 million in Lithium Americas, which is developing a mine in Nevada known as Thacker Pass. The deal makes G.M. the largest customer and shareholder of Lithium Americas.

Those investments could turn out to be money losers if the price of lithium continued to fall, analysts have warned.

There is also a risk that improvements in battery technology could affect demand for lithium in unexpected ways.

Solid-state batteries being developed by several companies would require even more lithium than batteries in use today, increasing demand. But those batteries probably won’t appear in mass-produced vehicles for several years. Other advances in production techniques and chemistry would allow batteries to be smaller and lighter without sacrificing performance, reducing the need for lithium.

Shifting technology has already hit cobalt. The price of that metal plunged in part because of the increasing popularity of batteries made without cobalt from lithium, iron and phosphate, a combination known as L.F.P. Stockpiling by a major cobalt supplier may also have hit prices, analysts say.

L.F.P. batteries are heavier than batteries made with cobalt, but they are significantly less expensive and last longer. And L.F.P. batteries don’t come with the taint associated with cobalt, most of which comes from the Democratic Republic of Congo, where mining operations are known for child labor and abysmal working conditions.

Ford Motor said in February that it would spend $3.5 billion to build a plant in Michigan to produce L.F.P. batteries using technology from Contemporary Amperex Technology, or CATL, a Chinese company that is the world’s largest battery manufacturer.

No technology on the horizon would eliminate lithium from mass-produced car batteries. For that reason, few analysts are predicting that the price of lithium will fall as low as it did in 2020, when it dropped below $10 per kilogram.

“Even when the price comes down from its elevated levels,” Ms. Natarajan, of Mobility Impact Partners, said, “there still is a very healthy profit margin.”